I've been searching all morning for a detailed description or article about white cotton candy and all I could find are pictures of modern spinning machines that produce the synthetic pink cotton candy on a stick. What you are going to see below is a premiere and an answer to many of your questions about our local, authentic, homemade white cotton candy or "Ghazl el Banet".

Ghazl el Banet is a originally a Turkish sweet which has been revisited the Lebanese way. Although the texture is similar to cotton candy, both methods and ingredients are different.

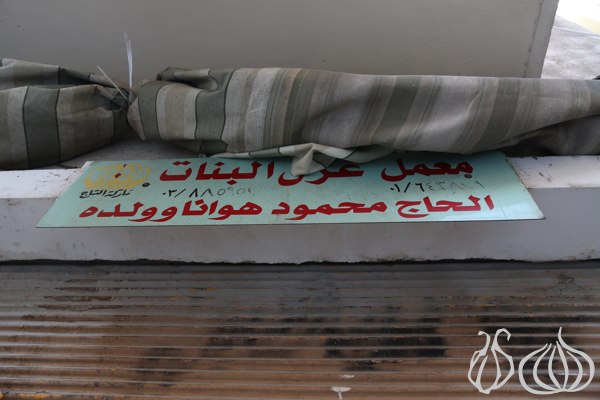

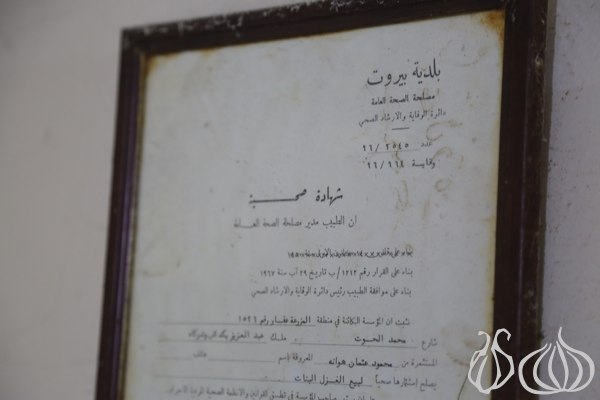

It was 9am when I reached Mahmoud Hawana's factory to meet with Bassam, Mahmoud's son, down in Ras el Nabe3, Beirut. They start working at 5am and by the time we got there, they had finished the day's production. But, courtesy of NGNO, they agreed to reproduce the whole process for the pleasure of your eyes. Before cotton candy existed, there was spun sugar, but before people could "spin" sugar, they had to caramelize it. This artisanal process is still being used by passionate artisans who transmit their know-how from a generation to another. Their hard work deserves some support and a moment of admiration. The process starts with the preparation of the caramelized sugar and cornstarch:

- Cornstarch is dehydrated for a full hour before being mixed with margarine

- The flour is then layered on a large metallic tray and kept to cool while the sugar caramelizes

- Meanwhile, the sugar is prepared. A secret family recipe creates a large bulky piece of caramel that will become Ghazl el Banet. Caramelization is what happens when sugar melts. A crystal of granulated sugar, scientifically called sucrose, is held together by chemical bonds, but energy from heat can break these bonds, splitting the crystal into its two component sugars, glucose and fructose. These sugars break down further, freeing their atomic building blocks: carbon, hydrogen and oxygen. Hydrogen and oxygen atoms reunite to form water, and the carbon clusters in increasingly larger clumps.

- After an intense mix of the caramel, a circular wheel is created and thrown over the flour bed

- And here the long meticulous process starts

- Stretching, turning around and duplicating the caramel wheel to become larger and larger creating thousands of meters of pure white cotton candy.

- Synchronization and stretching is important. Covering the mix with flour every time it is pulled is essential so it doesn't stick to each other. Synchronization is key for a process that takes around an hour or so

- Now that the process is done, packaging in plastic boxes comes next for export all around the world

Want to try doing it at home? Here's how it works:

- Cornstarch is dehydrated for a full hour

- The flour is then layered on a large metallic tray and kept to cool while the sugar caramelizes

- Meanwhile, the sugar is prepared. A large bulky piece of caramel is what will become become white Ghazl el Banet

- Stretching, turning around and duplicating the caramel wheel to become larger and larger creating thousands of meters of pure white cotton candy

- Strength, synchronization and stretching is important. Covering the mix with flour every time it is pulled is essential so it doesn't stick to each other. Synchronization is key for a process that takes around an hour or so

- Now that the process is done, beautiful pure white rolls are ready to be devoured

I can't describe my feeling after today's discovery. I sometimes get goosebumps just admiring the confidence of the men who believe in their know-how. Thank you for taking the time to explain your daily routine to us. We appreciate it. Now when you see one of these boxes, you know how they have been made.